From Concept

to Realization

End-to-end solutions for the Korean Pharma- and Biotech industries

ZETA Advantages

-

1

End-to-end solution provider for pharma & biotech

-

2

Time to market: With ZETA up to 50% faster to market

-

3

Customer-specific tailor-made system solutions

-

4

Permanent innovation and first-time-right approach

-

5

Complete digital value chain

As a globally operating end-to-end solution provider for the biopharma industry, ZETA specializes in the design, construction, automation, and qualification of customized systems for aseptic production processes. ZETA offers comprehensive solutions and services along the whole pathway of active substance development and manufacturing. In addition, ZETA serves as an EPCM contractor for major pharmaceutical projects, drives digital innovations, and develops comprehensive decarbonization strategies.

Digitalization

From integrated engineering to integrated operation solutions for your digital value chain

Back to overviewYour Advantages

-

1

End-to-end digital value chain

-

2

50% faster project implementation

-

3

Solutions for operations

-

4

Digital qualification & validation

-

5

Digitally supported maintenance & smart maintenance

Welcome to

the Industrial Metaverse

At ZETA, we specialize in providing cutting-edge digital solutions for engineering and operations. Our digital value chain covers the entire plant life cycle, from concept design to hand-over, commissioning, and operations. Our production simulations aim to maximize efficiency and savings, enabling your plant to unlock its full potential.

Optimize your pharma & biotech plant

with our innovative digital solutions!

- Smart Engineering Services:

up to 50% faster project execution - INOSIM:

simulations for fact-based engineering - Integrated Digital Testing:

faster FATs at highest quality - Smart Maintenance Navigator:

accelerate your maintenance - Foresight:

predictive decision support in plant operations

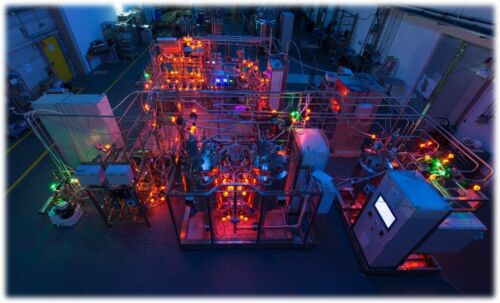

Process

Engineering

ZETA implements highly complex projects in the shortest possible time

Back to overviewYour Advantages

-

1

Time-to-Market:Get to market faster with us

-

2

Concentrated engineering competence from a single source

-

3

Full cost transparency through ongoing project control

-

4

Security and sustainability in the planning process

-

5

Many years of experience in plant engineering

Projects in record time

Time to market: With ZETA's project management

up to 50 % faster to market.

Engineering Solutions for the

Areas of Application:

-

API production

-

mAb production

-

Blood plasma processing

-

Vaccine production

-

Aseptic products

-

Emulsions

-

Chemical synthesis

-

Laboratory

-

Pilot

-

Production

Numerous planning steps are necessary from the laboratory to industrial production when developing active ingredients. Only through a thorough understanding of the process can errors and additional costs be avoided and rapid project implementation guaranteed.

Process Solutions

Your expert for large molecules, blood plasma, vaccines and parenterals!

Back to overviewYour Advantages

-

1

Higher production output & fewer losses

-

2

Custom solutions

-

3

Quality by design

-

4

In-house competence from CD to PQ

-

5

Compliance with all safety regulations and standards

From Upstream

to Downstream

Our solutions cover the entire biotechnological process!

Together with our customers, we develop bioreactors and fermentation systems for the extraction of active ingredients using cell, yeast and bacterial cultures. We supply tailor-made downstream systems for the processing, enrichment, purification and formulation of these biotechnologically manufactured products. The use of the most modern processes and techniques leads to the highest product yields with excellent quality.

Preparation Systems

From powder addition to agitator technology - ZETA has been a leader in the development of technical solutions for years. A decisive advantage in the design of preparation and media systems!

Fractionation

ZETA provides planning services and systems for all essential processes in blood plasma processing. A process with blood components as raw material places the highest demands on process management and system components.

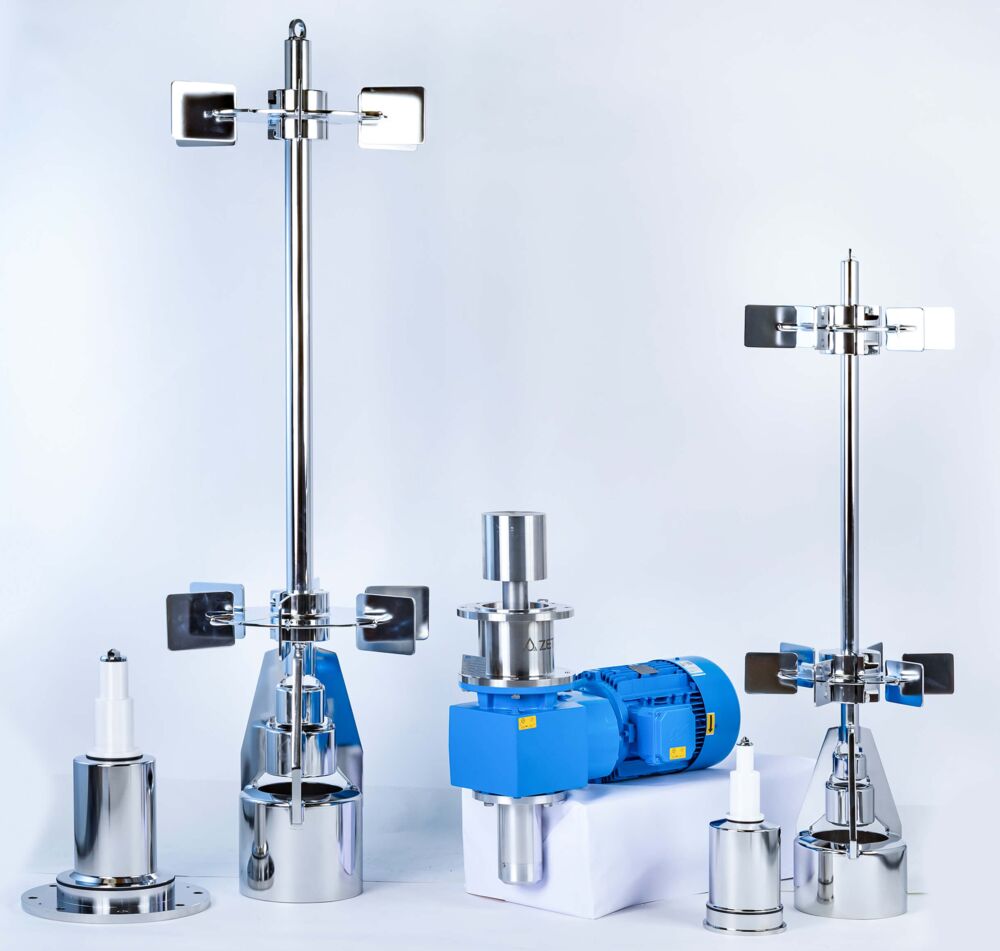

Mixing Agitator

ZETA magnetic mixers are the result of many years of experience with sterile design and know-how in process engineering.

Back to overviewYour Advantages

-

1

Hermetically Sealed Design

-

2

Performance & High Stability

-

3

Standard Solutions and Customer-specific Designs

-

4

Easy Installation and Maintenance

-

5

Easy Cleaning

-

BMRT

ZETA bottom-mounted magnetic agitators prove themselves particularly in special and demanding agitating tasks.

-

BMRF

Bioreactors with ZETA bottom-mounted magnetic agitators guarantee safe process control over long periods of time and can be used with containers up to 30,000 liters.

-

AMR

ZETA top-mounted magnetic agitators are practically maintenance-free and enable the use of all common agitating elements with a similar structure.

-

AMRi

A further development of the top-mounted magnetic agitator with internal magnetic coupling enables new areas of application and shows excellent stability even with an inclined agitator shaft.

Freeze & Thaw Systems

Temperature-critical solutions are controlled and evenly frozen with ZETA Freeze & Thaw systems.

Back to overviewYour Advantages

-

1

Shelf life over longer periods of time

-

2

Tailor-made

-

3

FreezeController

-

4

Scale-up

-

5

PilotFreeze

Freeze & Thaw Family of Products

-

1

Freeze & Thaw Systems for Freezing Proteins

From initial studies in LabFreeze to testing and optimization in the PilotFreeze system to the industrial Freeze system for freezing, transporting, storing and thawing. -

2

Freeze & Thaw Services

We support you in the systematic, knowledge-based process development for ideal transport and storage. -

3

FreezeContainer

Innovative containers for the optimal storage and transport of high-quality APIs: from 10 ml to 300L.

more Services

-

Solution

Solution -

Service

Service -

SolutionAutomation

SolutionAutomationSingle-usercontrol, DCS system or MTP? We have the right automationsolution for you!